Developed in the early 20th century, insulation resistance (IR) test is the oldest and most widely used test to evaluate insulation quality. Insulation resistance test is the second test required by the electrical safety test standard. Insulation resistance test includes measuring the insulation resistance of the tested equipment, and the phase line and neutral line are short circuited together. The measured resistance must be higher than the limit specified in international standards. Megohmmeter (also known as insulation resistance tester, megohmmeter) is used to measure the ohmic value of insulator under DC voltage with great stability.

Insulation cannot be perfect, just as something cannot be frictionless. This means that there will always be a little current through. This is called "leakage current". Good insulation is acceptable, but if the insulation deteriorates, leakage will begin to cause trouble. So, what is a "good" insulating material? Well, it needs a high resistance to current, and it needs to be able to maintain a high resistance for a long time

Why insulation resistance test?

The insulating material began to age. With the increase of age, its insulation performance will decline. Any harsh installation environment, especially extreme temperature and / or chemical pollution, will accelerate this process. Stress caused by different factors, such as:

1.Electrical stress: mainly related to overvoltage and undervoltage.

2. Mechanical stress: frequent startup and shutdown sequences will lead to mechanical stress.

3. Balance of rotating machinery and any direct stress on cables and general devices.

4. Chemical stress: the proximity of chemicals, oil, corrosive vapor and dust will usually affect the insulation performance of materials.

5. Stress related to temperature change: when combined with mechanical stress caused by startup and shutdown sequence, expansion and contraction stress will affect the performance of insulating material. Operation at extreme temperatures can also lead to material aging.

6. Environmental pollution leads to accelerated insulation aging.

This wear will reduce the resistivity of the insulating material and increase the leakage current, resulting in accidents that may have a serious impact on Safety (personnel and property) and shutdown costs. Therefore, it is important to quickly identify this deterioration in order to take corrective measures. In addition to measuring new and refurbished equipment during commissioning, regular insulation tests of devices and equipment can help avoid such accidents through preventive maintenance. These tests detect aging and premature deterioration of insulation properties before reaching a level that may lead to the above events.

This test is usually used as customer acceptance test, and the minimum insulation resistance per unit length is usually specified by the customer. The results obtained from IR tests are not as helpful to find local defects in insulation as in real hipot tests, but provide information about the quality of bulk materials used as insulation.

Wire and cable manufacturers use insulation resistance tests to track their insulation manufacturing process and identify problems before process variables deviate from allowable limits.

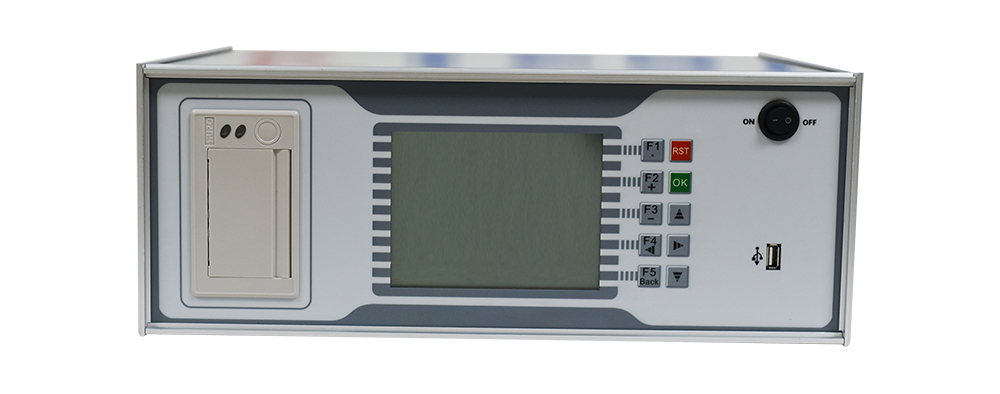

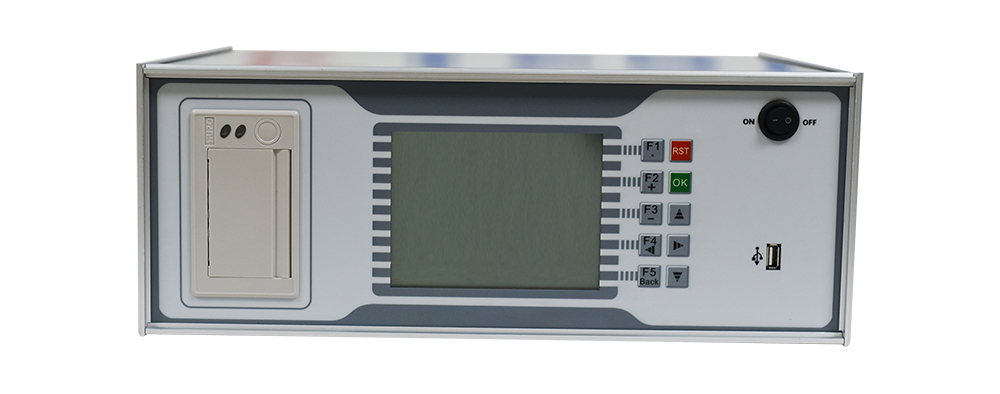

Kvtester specializes in the production of insulation resistance tester. It has been engaged in the electrical measurement industry for many years. Its products are of first-class quality. Customers are welcome to buy them.