The ultra-low frequency voltage withstand test is characterized by no damage to the tested cable, and it can also test the cable that is running and aging but can still be used. Therefore, it is a nondestructive voltage withstand test method.This kind of test is more accurate than the DC high voltage test in judging the connection error of newly laid cables and repaired cables at their joints and ends.

"Ultra low frequency (0.1Hz) withstand voltage test method for 35kV and below XLPE insulated power cables" industry standard. According to the requirements of this industry standard, the test procedure is as follows:

All electrical equipment connected to the test object shall be separated from the test object cable, and the test equipment (ultra-low frequency high voltage generator, etc.) shall be reliably grounded with bare copper wire.

Use a 10000v megger to conduct insulation resistance test on each phase of the cable under test, and record the test value.

Peak value of test voltage: 2UE, test time: 60min.

When the capacitance value of the test cable is within the load capacitance capacity of the test equipment, the three-phase cores of the test cable can be connected in parallel and the voltage withstand test can be carried out at the same time.

Connect the test equipment with the cable of the test object with a flexible connecting cable, turn on the power supply, and start boosting for the test. In the process of boosting, closely monitor the high-voltage circuit and monitor whether the cable of the test object has abnormal noise. When it rises to the test voltage, record the test time and read the test voltage value.

When the test time is up, first reduce the voltage to zero, and then cut off the power supply. If there is no destructive discharge during the test, it is considered to have passed the withstand voltage test.

In the process of boosting and withstanding voltage, if it is found that the pointer of voltmeter swings greatly, the indication of ammeter increases sharply, the voltage regulator continues to boost, but the voltage remains basically unchanged or even shows a downward trend, while the current increases greatly, and the cable of the test object emits peculiar smell, smoke, abnormal sound or flashing, etc., the boosting shall be stopped immediately, and the cause shall be found out after the step-down power failure. If these phenomena are found to be caused by the weak insulation part of the cable under test, it is considered that the voltage withstand test is unqualified. If it is determined that the test cable is caused by air humidity or surface dirt, the test cable should be cleaned and dried before the test.

During the test, if the test is interrupted due to the accidental loss of power supply due to the insulation defect of the non test cable, the full-time connection withstand voltage test shall be carried out again after finding out the cause and restoring the power supply. The "make-up time" test shall not be conducted only.

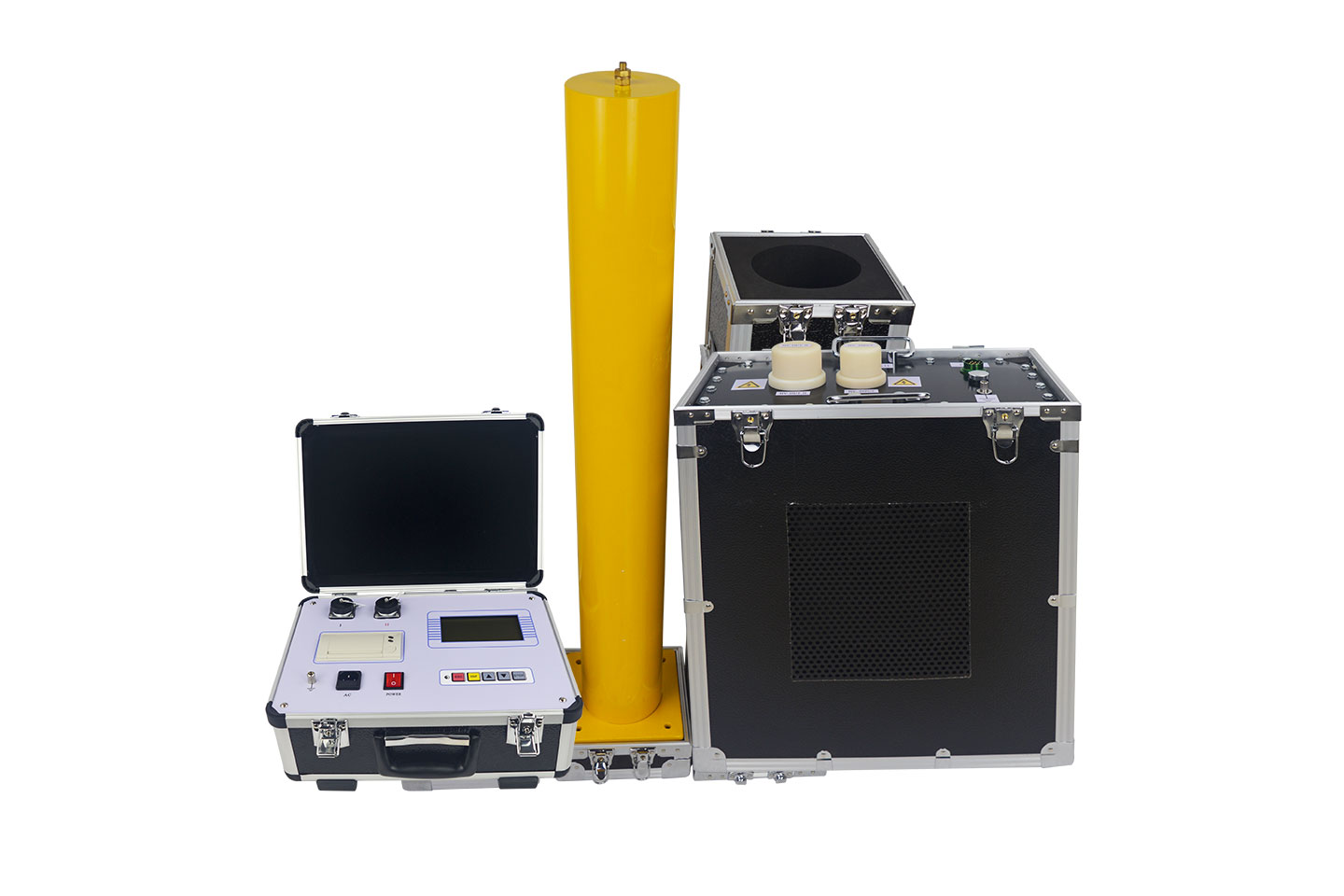

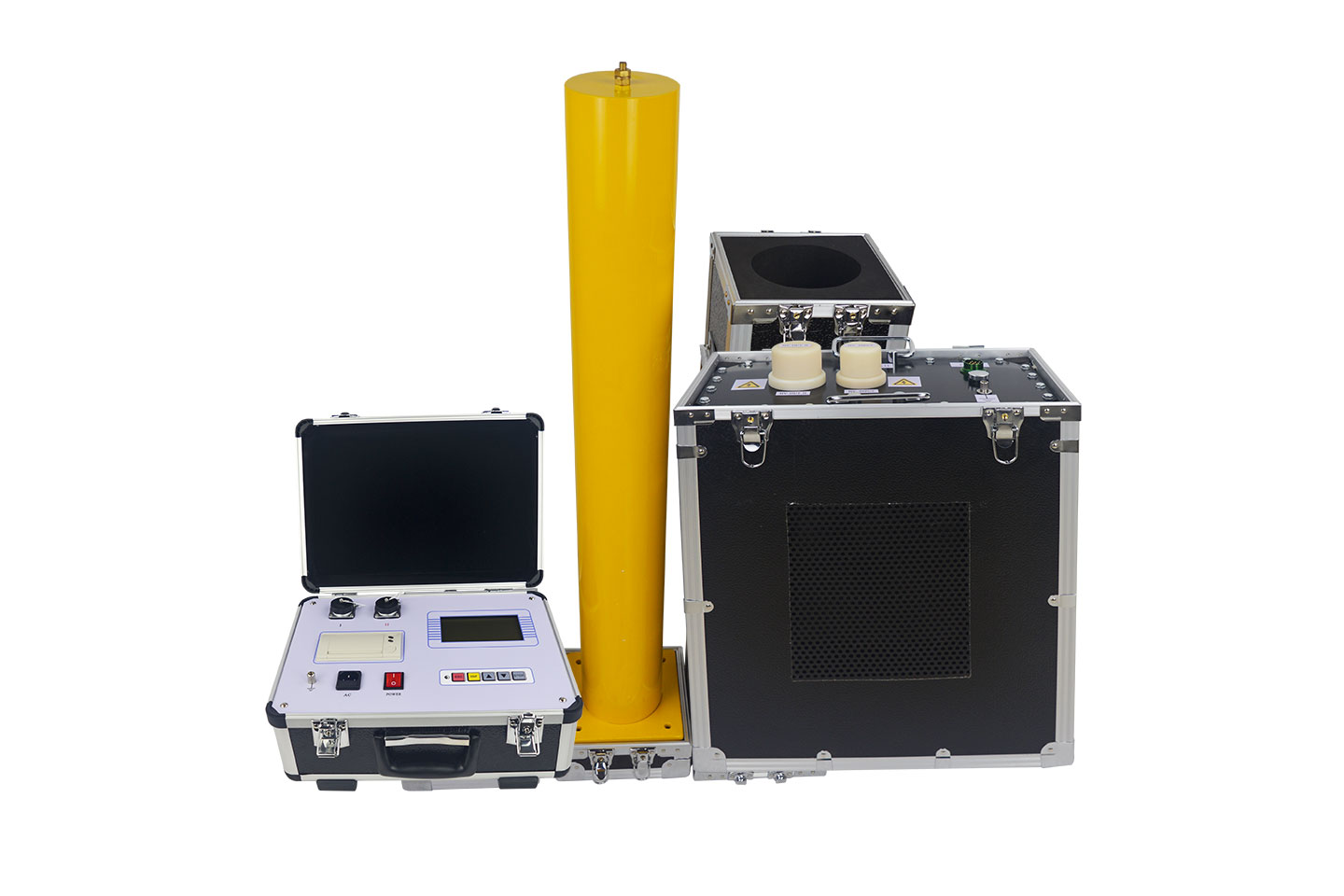

ZC-524B ultra-low frequency and high voltage generator combines modern digital frequency conversion advanced technology, adopts microcomputer control, and the boost, step-down, measurement and protection are fully automated, and manual intervention can be carried out in the process of automatic boost. Because it is fully electronic, it has small volume, light weight, large screen LCD display, clear and intuitive, and the printer outputs the test report. The design index fully conforms to the power industry standard of "general technical conditions for special testing instruments for power equipment, Part 4: General technical conditions for ultra-low frequency and high voltage generators", which is very convenient to use.