Introduction to winding deformation function

The transformer winding deformation tester is a specialized testing instrument used to measure the deformation of transformer windings according to the power industry standard DL/T911-2004. Power transformers are inevitably subjected to various faults, short-circuit currents, or physical impacts during operation or transportation. Under the strong electric force generated by short-circuit currents, the transformer winding may lose stability, leading to permanent deformation phenomena such as local distortion, bulging, or displacement, This will seriously affect the safe operation of the transformer, so it is essential to check the winding condition of the transformer.

Principle and method

The testing principles for judging the condition of transformer windings mainly include low voltage short-circuit impedance method and frequency response method.

Frequency response principle

The frequency response method uses a scanning generator to apply a set of sine wave voltages of different frequencies to one end of the transformer winding, and then collects characteristic parameters of the winding ports at both ends, such as the frequency response curves of input impedance, output voltage, and current transfer ratio. By analyzing the frequency characteristics of the port parameters, the structural characteristics of the winding are determined. If the winding deforms, the distributed capacitance and inductance will change, The frequency spectrum reflecting port parameters may change. For the same type of transformer winding, due to the similarity of winding structure, the measured frequency response curve must be comparable. Therefore, the frequency response method determines the degree of deformation of transformer windings through the response curves before and after fault collection.

Functional features: Wireless Bluetooth interface, fast testing speed, integrated circuit board, good stability and reliability, with linear scanning and segmented scanning, as well as domestic two technologies.

Principle of Low Voltage Short Circuit Impedance Testing

When the load impedance of a transformer is zero, the internal equivalent impedance of the transformer, the reactance component of the short-circuit impedance, namely the short-circuit reactance, is the winding leakage reactance. The leakage reactance is determined by the geometric shape of the winding. For a transformer, when the winding deforms, the geometric shape changes, and the short-circuit reactance value also changes. If the operation of the transformer is affected by the short-circuit current, in order to check whether the winding is deformed, The short-circuit reactance before and after the short-circuit can be compared, and if it can be considered that the winding deformation is significant.

Generally, low-voltage short-circuit impedance testing is conducted in the field of power transformers, and compared with the values measured on the nameplate or before the short-circuit fault to determine whether there is significant deformation of the winding causing serious fault short-circuit current. The disadvantage is that the impedance method for transformer winding deformation testing is particularly suitable for 35kV and above. For transformers below 35kV, the impedance method is used. The short-circuit impedance method can only qualitatively measure the transformer and can only display whether there is a fault, but cannot display the fault waveform.

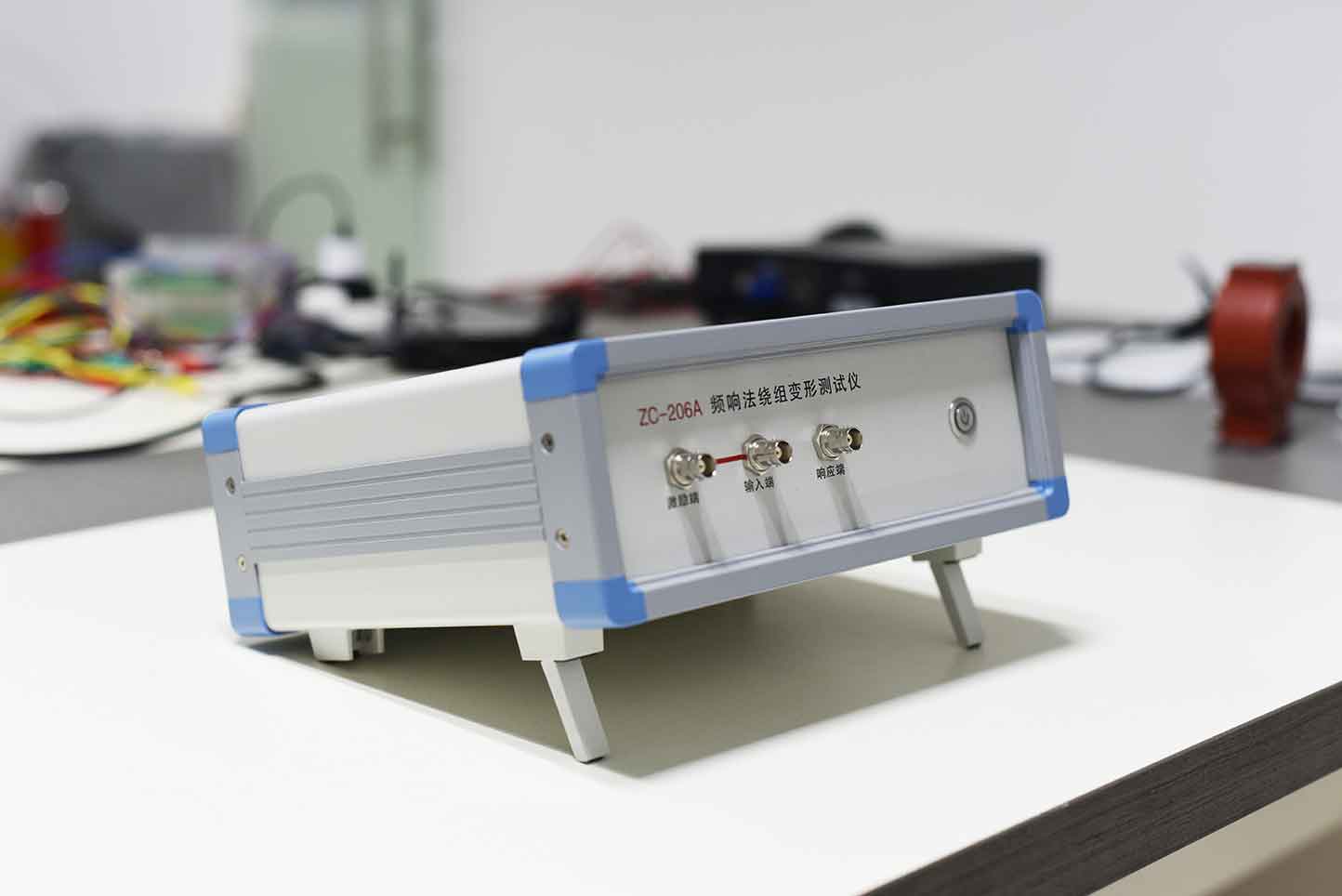

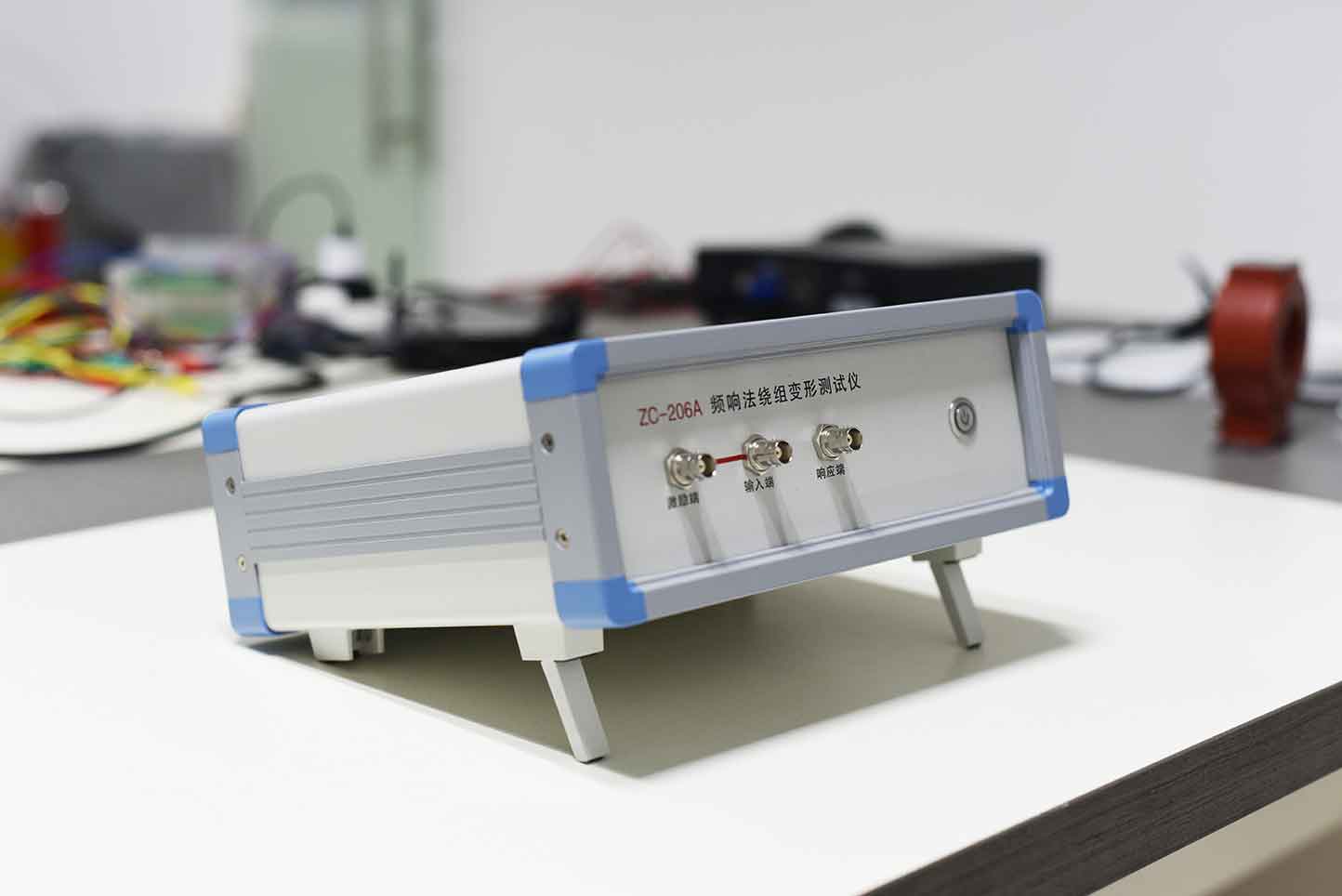

The ZC-206A Transformer Winding Deformation Tester is used to test the winding deformation of power transformers with voltage levels of 6kV and above, as well as other special purpose transformers. During operation or transportation, power transformers are inevitably subjected to various faults, short-circuit currents, or physical impacts. Under the strong electric force generated by short-circuit currents, the transformer winding may lose stability, leading to local distortion, bulging, or displacement, which will seriously affect the safe operation of the transformer. According to the national power industry standard DL/T911-2004, the frequency response analysis method is used to measure the winding deformation of transformers. It detects the amplitude frequency response characteristics of each winding of the transformer and compares the detection results vertically or horizontally. Based on the degree of change in amplitude frequency response characteristics, the possible deformation of the transformer winding is determined.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase.