1. Operation method:

① Instrument panel and wiring instructions:

The instrument panel is shown in Figure 2. The leak detection key is used to preliminarily judge the vacuum degree of the vacuum tube, and the measurement key is used to apply high voltage and strong electromagnetic field to quantitatively test the vacuum degree of the vacuum tube. There is a high-voltage output terminal on the side of the instrument, which can be connected to a contact of the vacuum tube with a high-voltage wire. The ion current input terminal is connected to another contact of the vacuum tube. The two output terminals of the magnetic field voltage should be connected to the two wiring terminals of the excitation coil. The grounding terminal is used for the protective grounding of the instrument casing. The tube type input pull-out switch is used to input the tube type of the arc extinguishing chamber. The tube type of the arc extinguishing chamber is determined directly by the arc extinguishing chamber, and for those with an outer cover, the diameter of the outer cover shall prevail.

② Tube type selection:

Ceramic and glass arc extinguishing chamber pipes with a diameter less than 80mm are classified as 00 pipe types

02 pipe type with a diameter greater than 80 mm but less than 100 mm

Type 04 for pipes with a diameter greater than 100mm but less than 110mm

06 pipe type with a diameter greater than 110 mm

Indoor epoxy resin fully enclosed arc extinguishing chamber, 6000V and below arc extinguishing chamber selected with tube type 01

③ Perform leak detection:

Leak detection should be performed before testing the vacuum level. When checking for leaks, attention should be paid to whether the outside of the vacuum tube is wiped clean and dried. If the vacuum tube has serious leakage, there is no need to conduct a quantitative vacuum test. If the leak detection is qualified, a quantitative test can be conducted again.

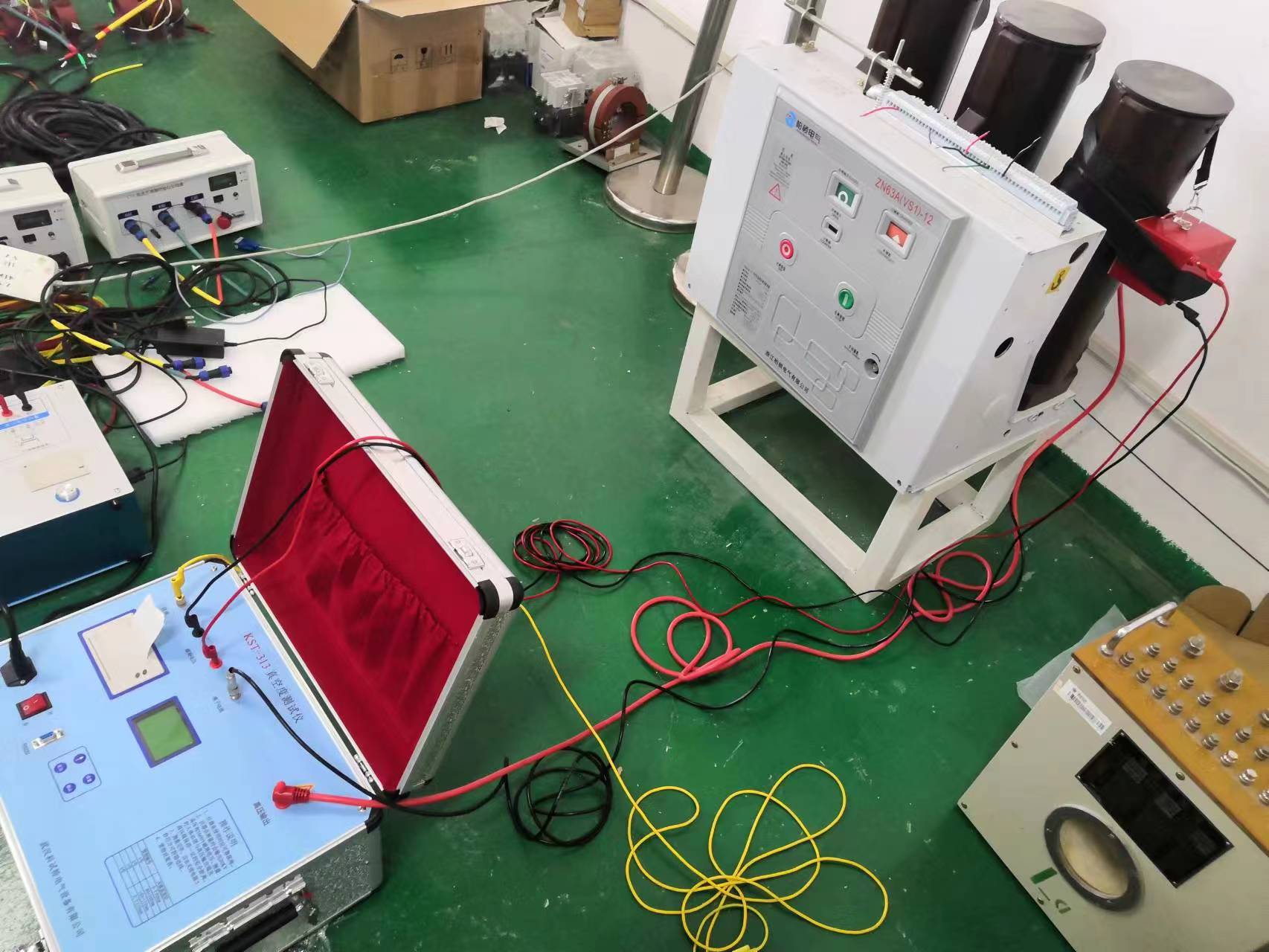

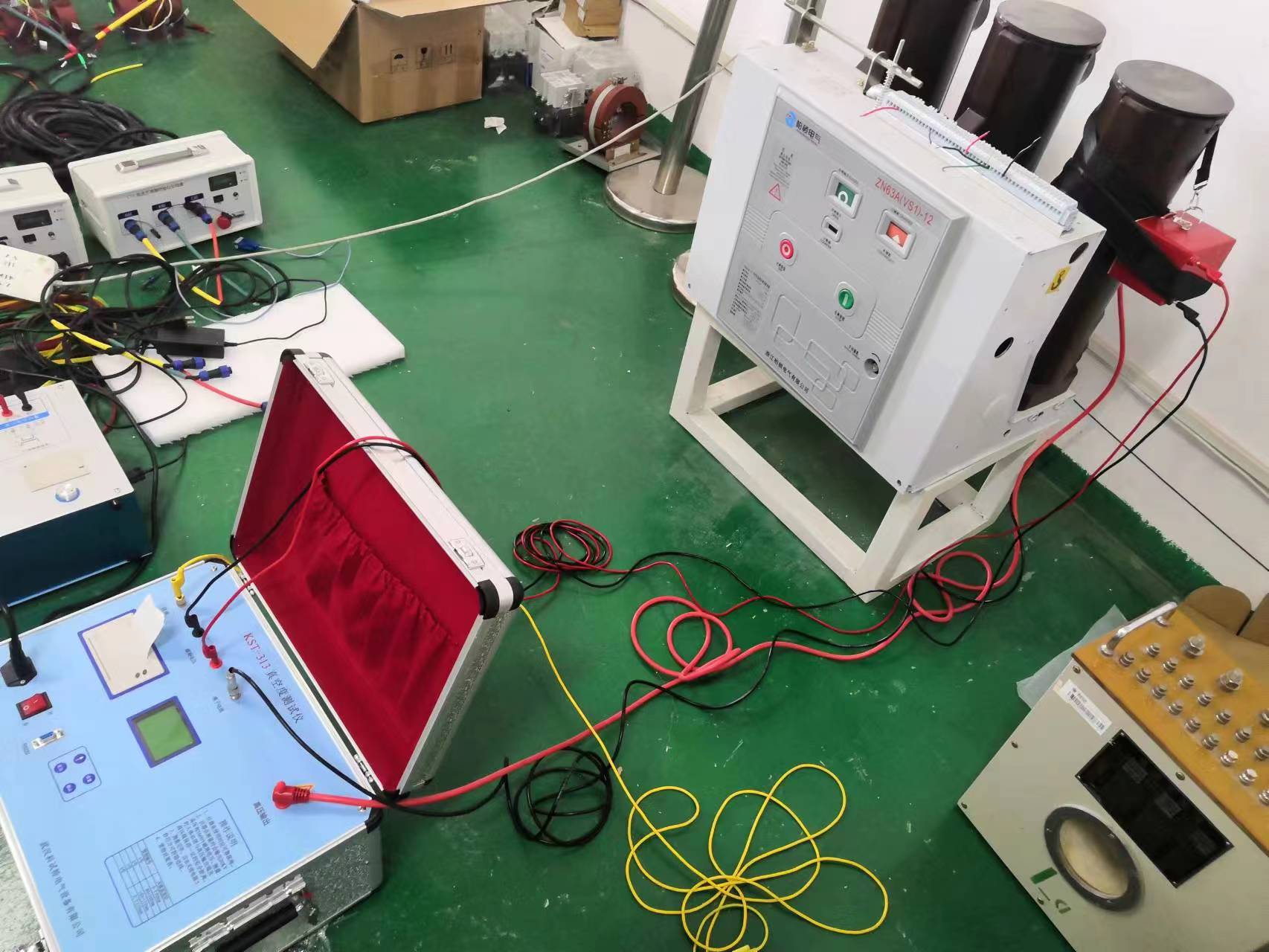

④ Conduct testing:

After pressing the test button, the tester first displays the electric field voltage and magnetic field voltage, and performs the automatic charging process. When the two voltages reach a certain value, the tester automatically applies the electric field voltage and magnetic field voltage to the vacuum tube and excitation coil. At the same time, it automatically starts the testing and analysis program, displays the test results of the tested vacuum tube, and automatically discharges the internal capacitance of the instrument. (Display result: 3.26E-4Pa is 3.26 × 10-+Pa Pascal)

The minimum measurement value of this instrument is 1.06 × 10 * Pa, if the vacuum degree of the tested vacuum tube is better than this value, the displayed result is still 1.06 × 10 Pa. For vacuum circuit breakers, it indicates that the vacuum degree of the vacuum bubble is intact, and when recording the test results, it can be recorded as<10'Pa. If the vacuum degree is greater than 6.6 × 10 Pa, then the vacuum bubble is unqualified.

When testing the same vacuum tube multiple times, the interval between adjacent measurements should not be less than 10 minutes. At the same time, turn off the power of the instrument, short circuit the ion current clamp to the high-voltage output terminal clamp, eliminate residual high voltage, and then proceed with the next test. Otherwise, the ionized air inside the tube may not be able to return to its normal state in time, resulting in distorted test results.

⑤ Arc suppression discharge:

Press the leak detection button to detect leaks, reduce the magnetic field voltage, press the reset button after the action is completed, and then shut down. Discharge the large clamp at the high voltage output end to the ground, or lightly touch the vacuum tube end clamped by the high voltage clamp with a discharge rod, or short-circuit the ion current clamp with the high voltage terminal wire clamp to eliminate residual high voltage and static electricity generated during the test process.

2. Notes:

① The vacuum degree test should be carried out in sunny and dry weather, and the surface of the vacuum bubble should be wiped clean. Leakage caused by the dirty surface of the vacuum bubble will seriously affect the actual test results of the vacuum degree. The vacuum degree test of the same vacuum switch should have a minimum interval of 10 minutes between each test. Otherwise, the ionized air inside the tube may not be able to return to its normal state in time, resulting in distorted test results.

② It is recommended not to test the vacuum degree of the same vacuum switch more than three times a day.

③ When testing the vacuum degree, leakage should be detected first, and quantitative testing should be carried out after passing the leakage detection.

④ When installing the excitation coil, its positioning indicator line points towards the middle seam of the arc extinguishing chamber connection.

⑤ During the testing process, the human body should not come into contact with the high voltage and magnetic field voltage output terminals, and the shell of the tester should be grounded.

⑥ The high-voltage output line and ion current line should be separated to prevent interference.

⑦ The magnetic field voltage line should not be short circuited, otherwise it will seriously damage the instrument and personal safety! Before the experiment, the yellow green line must be connected to the electromagnet and then to the instrument; After the experiment, pull out the yellow and green test wires from the instrument separately (do not touch the exposed parts of the plug-in with your hands).

⑧ After the test is completed, the power should be turned off and the high-voltage output terminal should be short circuited to ground for discharge to avoid being shocked by residual voltage on the charging capacitor.

The ZC-313 vacuum tester abandons the traditional withstand voltage method and uses the magnetic discharge method for measurement, so there is no need to disassemble the arc extinguishing chamber. The use of a single-chip microcomputer for synchronous control and data acquisition processing improves the on-site testing sensitivity of the vacuum degree in the arc extinguishing chamber. This product has a compact structure, a lightweight and compact model, shorter testing time, higher measurement reliability, stability, accuracy, and more complete functions.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com