The methods for ensuring the stability of a DC high-voltage generator mainly involve multiple aspects in its design, manufacturing, and use process. The following are key measures and factors:

1. High quality components and materials: Firstly, the use of high-quality electronic components, insulation materials, and structural materials is the foundation for ensuring equipment stability. High quality components can reduce performance fluctuations caused by material aging, damage, and other factors during equipment operation.

2. Advanced control strategy: The DC high-voltage generator adopts advanced control strategy, which monitors and adjusts the power output in real time through a microprocessor or digital signal processor. This closed-loop control system can automatically adjust the output voltage and current according to factors such as load changes and temperature changes, ensuring that the equipment can maintain stability under various working conditions.

3. Good heat dissipation design: Due to the large amount of heat generated by high-voltage generators during operation, good heat dissipation design is crucial for ensuring equipment stability. By adopting efficient heat dissipation measures such as heat sinks and fans, the temperature of the equipment can be effectively reduced, preventing performance degradation or equipment damage caused by overheating.

4. Comprehensive protection mechanism: DC high-voltage generators are usually equipped with multiple protection mechanisms, such as overvoltage protection, overcurrent protection, overheating protection, etc. These protection mechanisms can quickly cut off the power or adjust the working status in case of equipment abnormalities, preventing equipment damage or safety accidents.

5. Regular maintenance and calibration: In order to ensure the long-term stability of the equipment, it is necessary to regularly maintain and calibrate the DC high-voltage generator. This includes cleaning equipment, inspecting fasteners, replacing aging components, calibrating output voltage and current, etc.

6. Correct usage method: When using a DC high-voltage generator, users should follow the operating procedures and precautions of the equipment to avoid misoperation or overloading. At the same time, regular self inspection and preventive maintenance should be carried out on the equipment to ensure that it is in the best working condition.

In summary, the DC high-voltage generator can ensure its stability and reliability during operation by adopting high-quality components, advanced control strategies, good heat dissipation design, comprehensive protection mechanisms, and regular maintenance and calibration measures.

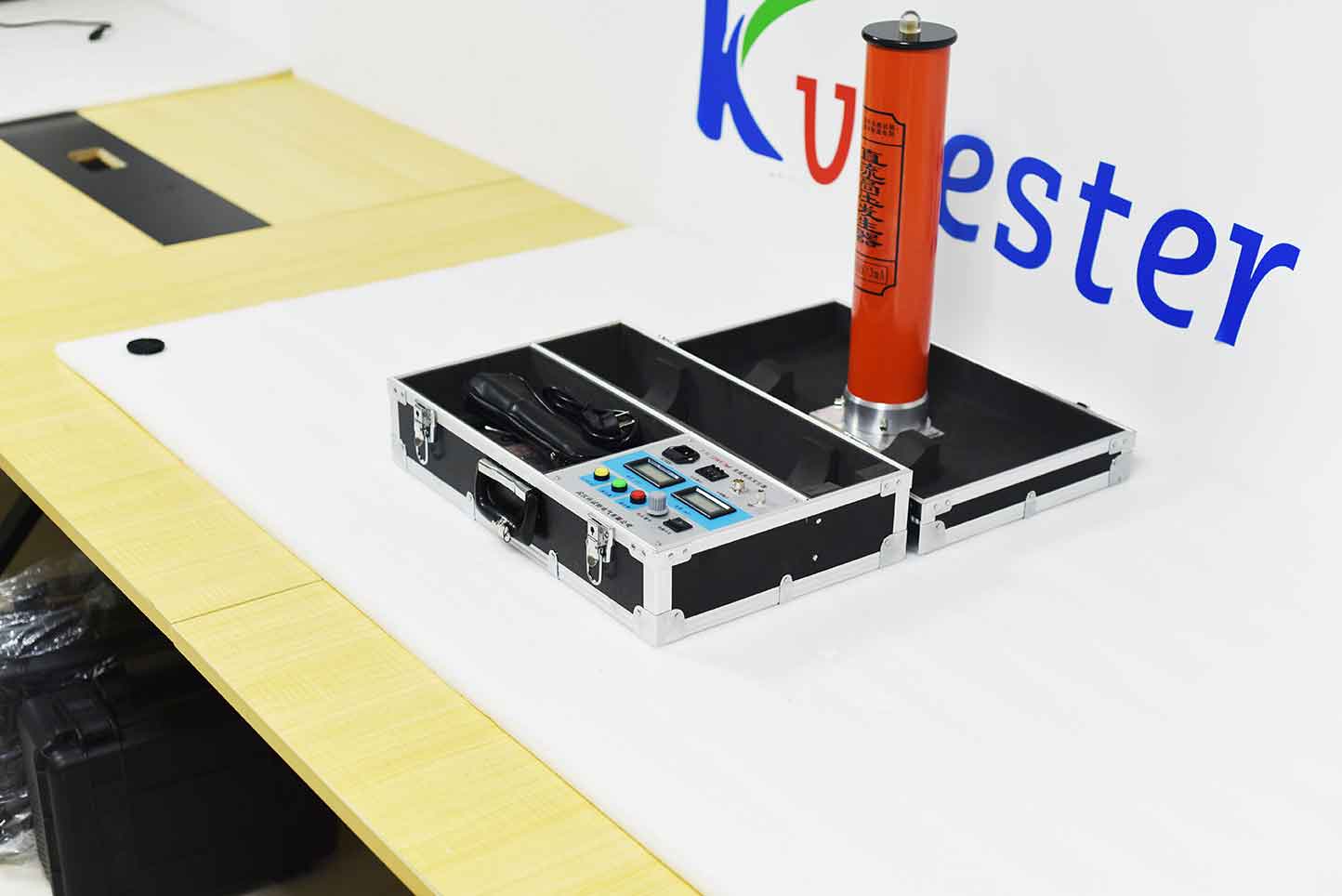

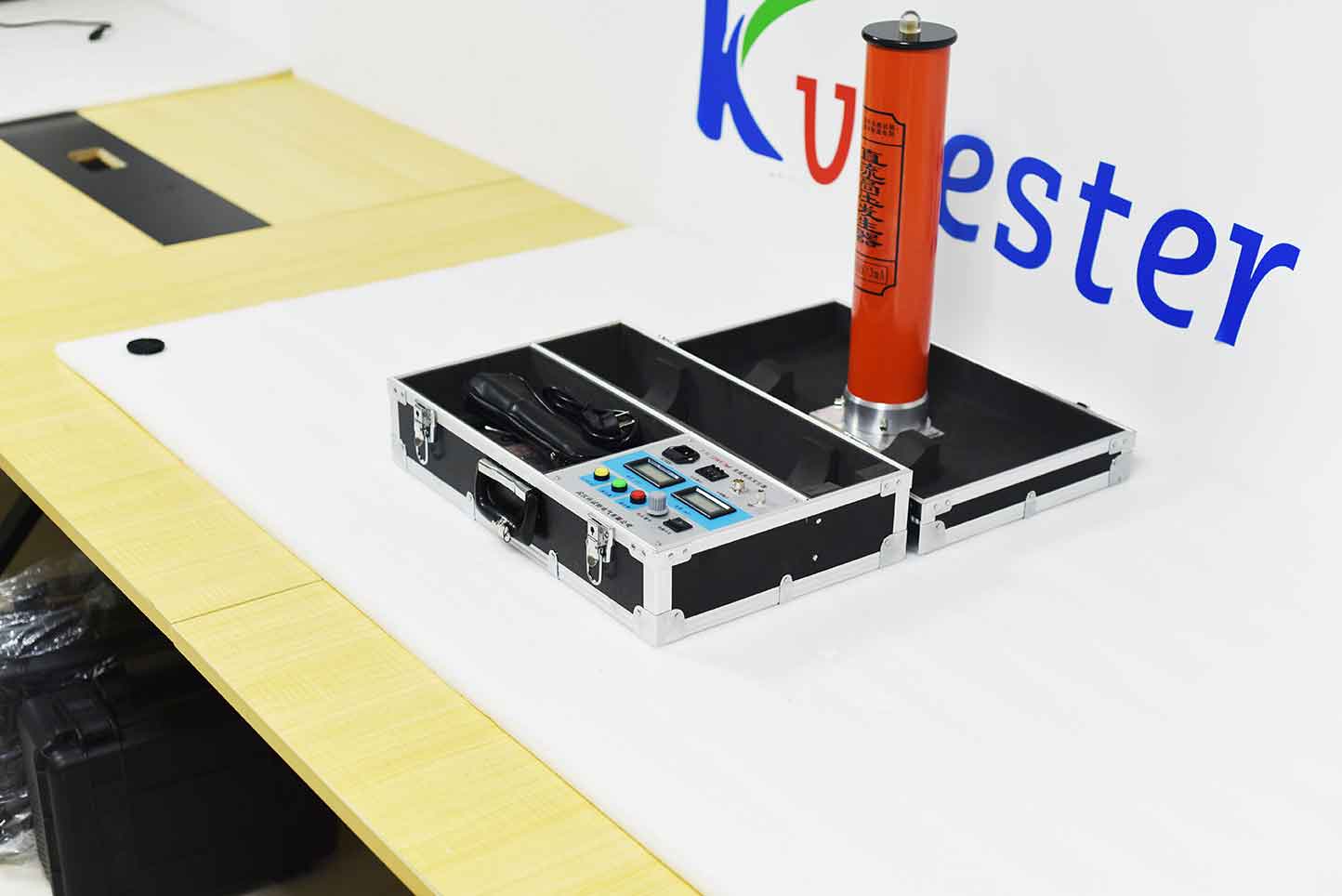

The ZC-540A DC high-voltage generator is mainly suitable for conducting DC withstand voltage tests on high-voltage electrical equipment such as zinc oxide lightning arresters, magnetic blowing lightning arresters, power cables, generators, transformers, switches, etc. in the power sector, power departments of factories and mining enterprises, scientific research institutions, railways, chemical industries, power plants, etc. The instrument adopts an intermediate frequency voltage doubling circuit and PWM intermediate frequency pulse width modulation technology, which greatly improves voltage stability. According to electromagnetic compatibility theory, special shielding, isolation, and grounding measures are adopted to discharge the DC high-voltage generator at rated voltage without damaging the instrument.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com