1. Preparation work

① Confirm power supply: First, confirm if the power supply of the load tester is sufficient and connect the adapter. It is recommended to use a grounded power outlet to ensure safe use.

② Connecting equipment: Connect the load tester to the battery to be tested to ensure stable and reliable connection. At the same time, check the communication configuration between the testing devices to ensure that the IP address and port number are set correctly.

③ Environmental preparation: Ensure the safety of the testing environment and avoid working under excessive voltage and current limits. In addition, it is best to develop a testing plan before testing, including setting testing scenarios and selecting testing metrics.

2. Basic operations

① Start the instrument: Press the power button of the load tester, and after the device is started, the main interface will be displayed on the screen. At this point, the device can be operated through the touch screen or buttons.

② Set test parameters: In the main interface, select the "Create Scene" option. According to the testing requirements, set parameters such as load type, number of concurrent users, and request frequency. The setting of these parameters will directly affect the test results, so it is necessary to customize the settings according to the actual situation.

③ Start testing: After setting up the testing scenario, click the "Start Testing" button. The load tester will start simulating user behavior and send a request to the battery to be tested. At the same time, the device will monitor the performance indicators of the battery in real time and record relevant data.

④ Monitoring the testing process: During the testing process, various indicators such as voltage, current, response time, etc. can be monitored on the screen. In addition, the load tester also provides a graphical display function to more intuitively observe changes in battery performance.

⑤ End Test: When the test reaches the preset conditions or needs to be manually ended, click the "Stop Test" button. The load tester will stop simulating user behavior and generate a test report. The report will provide detailed records of various indicators and results during the testing process, providing strong support for the performance evaluation of batteries.

3. Precautions

① Safe operation: During the measurement process, be sure not to touch the metal part of the test line to avoid electric shock. At the same time, the measurement wiring must be strictly operated according to the instructions to ensure the safety and reliability of the testing process.

② Reasonable parameter setting: Reasonably set the parameters of the testing scenario to ensure the stability and effectiveness of the testing process. Avoid the potential impact of excessive load on the battery, while ensuring sufficient system resources and avoiding issues such as system crashes or service interruptions caused by testing.

③ Maintenance and upkeep: If the load tester is not used for a long time (more than three months), the battery may be depleted and damaged. Therefore, it is recommended to charge the instrument every 3 months (after turning it on, the battery level should be displayed as around 90%) to ensure that the instrument can be used normally.

Through the above steps and precautions, I believe you can better grasp the usage of the battery load tester and provide accurate and reliable data support for battery performance evaluation.

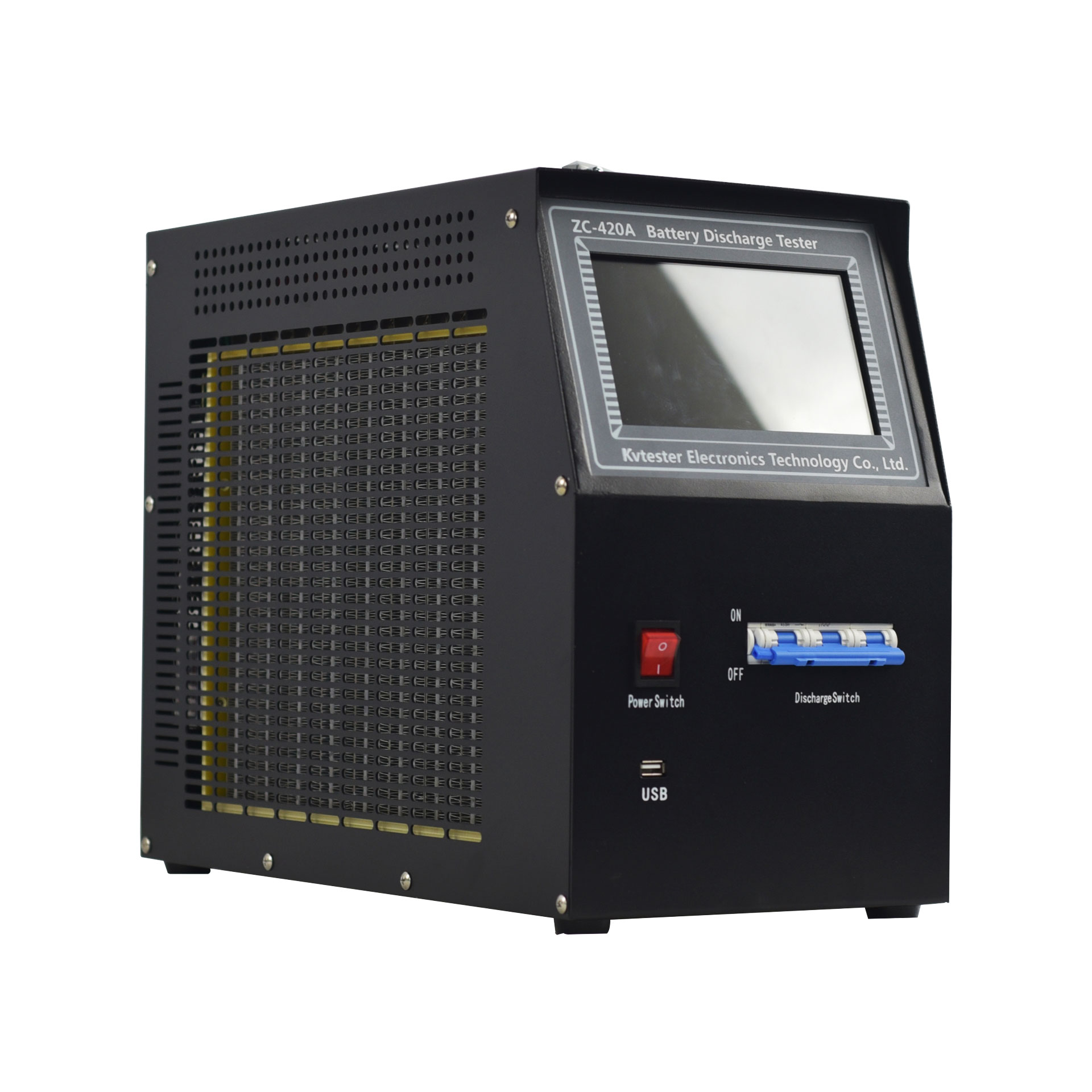

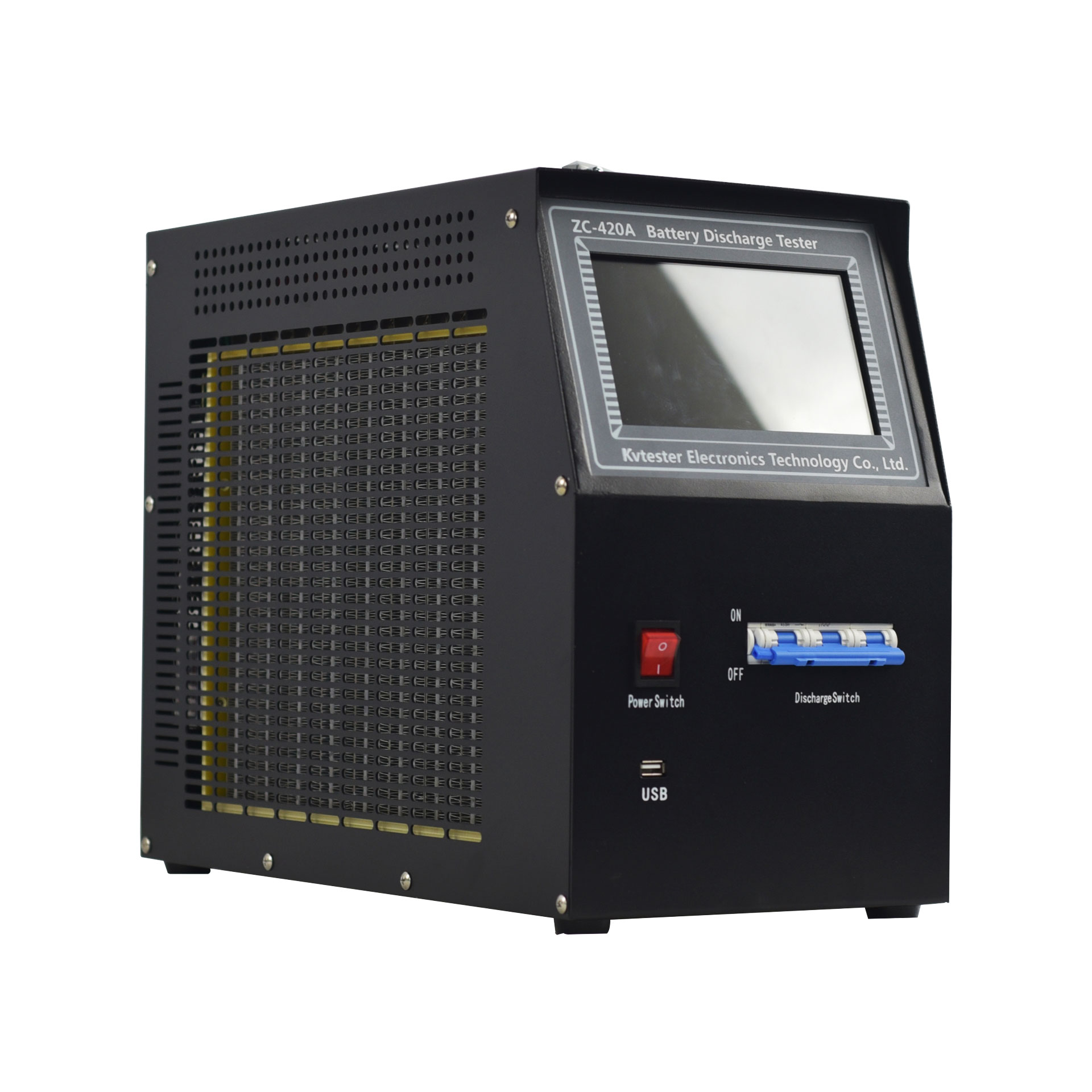

ZC-420A battery load tester is specifically designed for conducting verification discharge experiments, capacity testing, daily maintenance of battery packs, engineering acceptance, and other DC power load capacity tests on battery packs. Using wireless communication technology, the discharge process of the battery can be monitored in real-time through PC monitoring software, monitoring the discharge process of each battery. The power consumption of the instrument adopts a new type of alloy resistor as the discharge load, which is safe, reliable, pollution-free, and stable. The whole machine is controlled by a 32bit ARM microprocessor, with a 5.7-inch LCD touch display, Chinese menu, and multiple interfaces for users to choose from according to their needs. The appearance design is novel, small in size, light in weight, and easy to move. After setting various discharge parameters, the entire discharge process is automatically completed.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com