Preventive testing of power systems refers to the regular or irregular inspection and testing of power equipment that has already been put into operation, in accordance with prescribed testing conditions (such as testing equipment, environmental conditions, testing methods, and testing voltages), testing items, and testing cycles. This experiment aims to discover hidden dangers in the operation of power equipment, prevent accidents or equipment damage, ensure the safe operation of equipment, and thus improve the overall reliability and economy of the power system.

The main contents and purposes of preventive testing in power systems include:

1. Insulation test:

Insulation resistance testing, dielectric loss tangent testing, partial discharge detection, etc. are used to evaluate the condition of insulation materials and ensure that equipment can maintain safety and stability under normal operation and abnormal conditions.

2. Grounding resistance test:

Ensure the reliability of the grounding system and prevent electrical accidents caused by poor grounding.

3. Equipment specific tests:

① Circuit breaker test: including testing of opening and closing time, closing speed, contactor contact resistance and other parameters to ensure that the circuit breaker can quickly cut off the circuit in case of a fault.

② Transformer test: including no-load test, short-circuit test, insulation oil test, etc., to evaluate the operating condition of the transformer.

③ Cable testing: Testing the insulation resistance, leakage current, and withstand voltage of cables to evaluate their insulation status.

④ Lightning arrester test: Check the conduction current, leakage current and other parameters of the lightning arrester to ensure that it can work normally under lightning impulse.

⑤ Relay protection device test: Test the operating characteristics, setting values, etc. of the relay protection device to ensure that it can operate accurately in the event of a fault.

4. Online monitoring:

Real time monitoring of the operating status of power equipment using sensors and monitoring systems to detect anomalies in a timely manner.

5. Data analysis and evaluation:

The collected test data needs to be analyzed in detail and compared with historical data to see if there is a trend of performance degradation. All test results should be recorded in detail and compiled into a report, which should include the problems discovered during testing and suggested improvement measures.

6. Maintenance and Overhaul:

Based on the test results and maintenance status, update the equipment maintenance plan, optimize resource allocation, and improve the efficiency of equipment management. For problems discovered during testing, immediate maintenance or replacement should be arranged to prevent more serious malfunctions from occurring in the future.

Preventive testing of power systems is usually conducted in accordance with relevant national or industry standards, such as the "Regulations for Preventive Testing of Power Equipment". These standards specify the testing cycle, methods, and technical requirements. With the advancement of power equipment technology, the methods and means of power preventive testing are constantly being updated, such as the introduction of new technologies such as infrared detection and ultrasonic detection, which have improved the accuracy and efficiency of the testing.

In short, preventive testing of the power system is one of the important measures to ensure the safe and reliable operation of the power system, and is of great significance for improving the overall performance and economy of the power system.

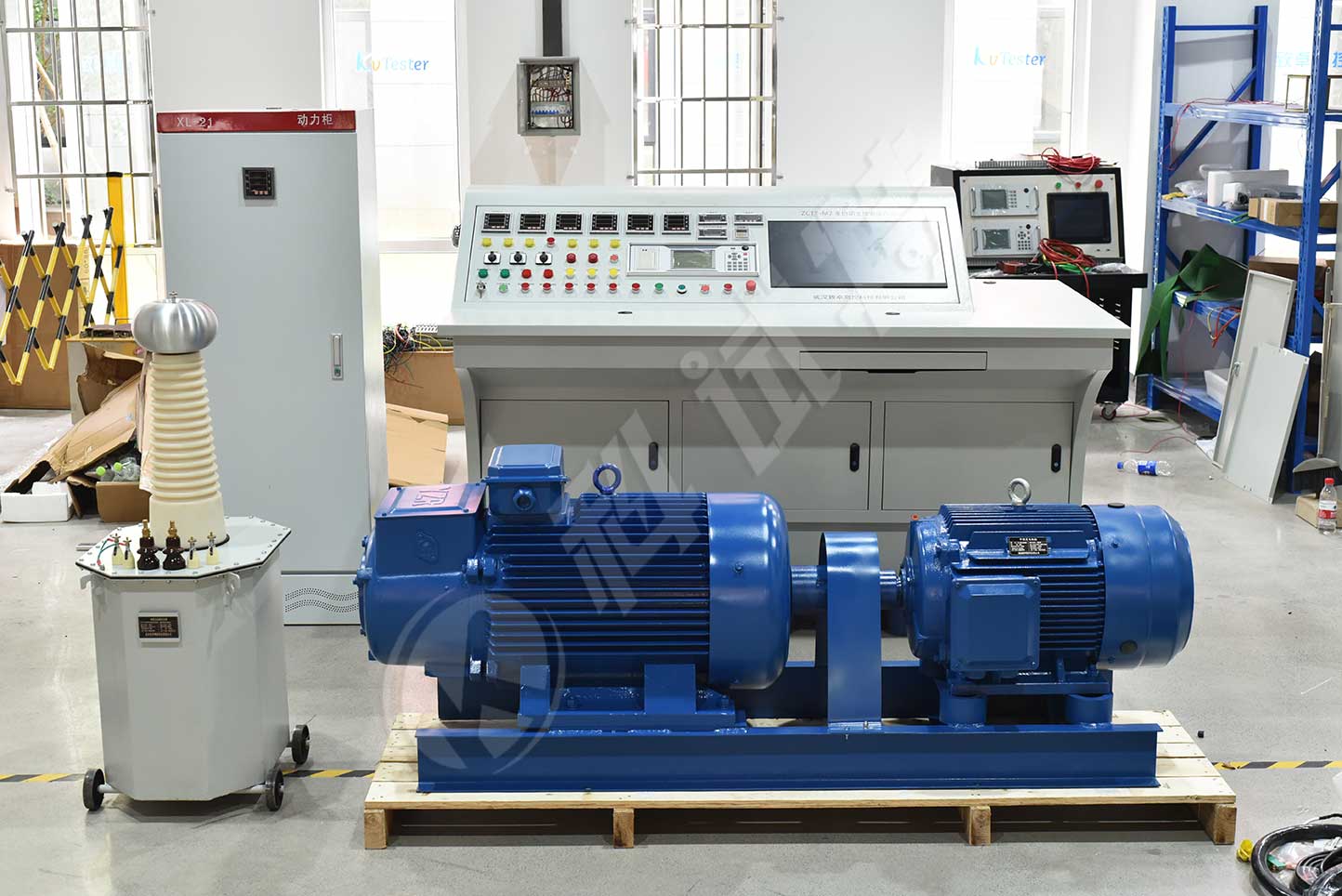

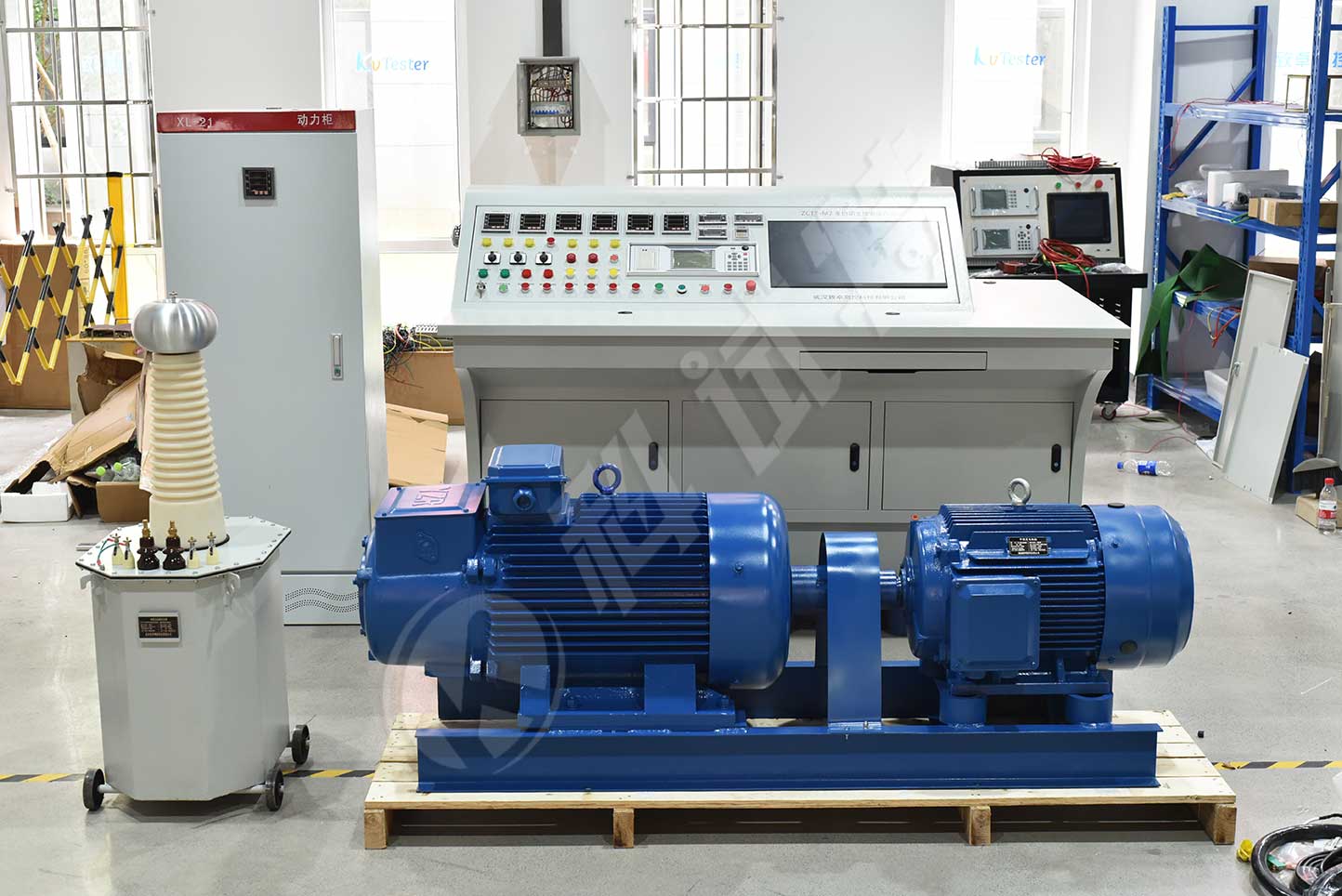

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com